Quality and Reliability are objectives, that accompany each stage of production.

"To achieve motto of zero defects", the quality management system is implemented in every stage and well equipped with the quality equipments and labs in the casting and machining facilities.

Quality Assurance in Foundry is crucial to ensure consistency and excellence in the final product. Quality Assurance Department is responsible for final checks and sign-off prior to dispatch according to our QA process.

| Equipment Name | Make | Range / Capacity |

|---|---|---|

| Carbon Silicon Analysis | Suyash | 1000°-1700° |

| Carbon Silicon Analysis | Ajay sysycon | 1000°-1700° |

| Temperature Analyzer | Suyash | 1000˚-1700° |

| Spectra Analyzer | Metal Power | M108E |

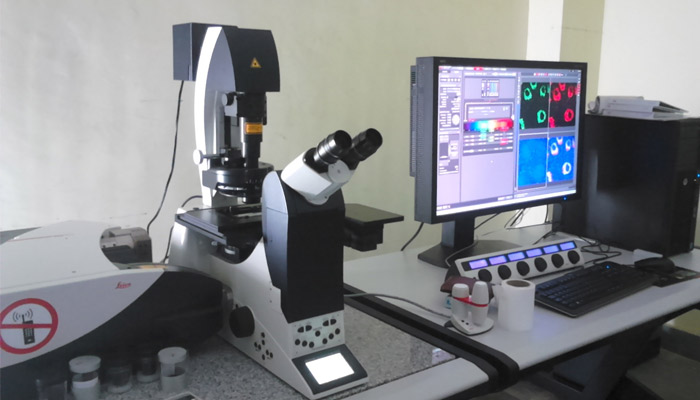

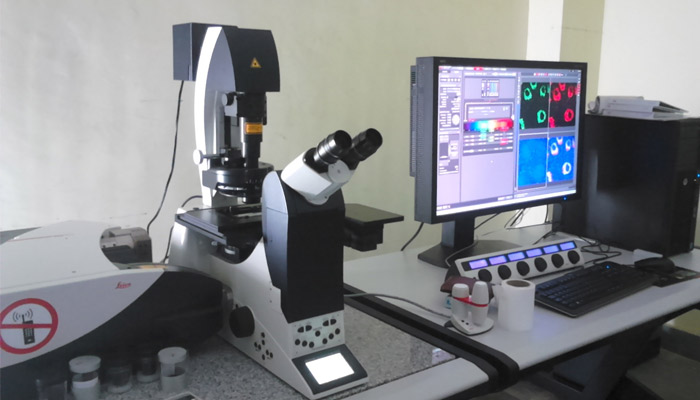

| Microscope | Metzer | |

| Brinell Hardness Tester | Fine | 3000 Kgs |

| Rockwell Hardness | Fine | |

| Poldi Hardness Tester | Versatile | |

| Core Hardness Tester | Versatile | |

| Mould Hardness Tester | Versatile | 0-100 lbs./inch² |

| Rapid Moisture Tester | Versatile | 0-10% |

| Rapid Dryer | Versatile | |

| Sand Rammer | Versatile | |

| Compatibility Tester | Versatile | |

| Clay Washer | Versatile | |

| Permeability Meter | Versatile | |

| Universal Strength Machine Hydraulic | Versatile | |

| Dry Strength Attachement | Versatile | |

| UTM | Kelson |

Quality control of our machining operations is done by the operators themselves by suitable Guages. Quality control aspects and prospects to reduce job rework and rejections.

Copyright 2023 @ S N S Alloy Castings. All Rights Reserved. Designed by: Vaishnavi K A